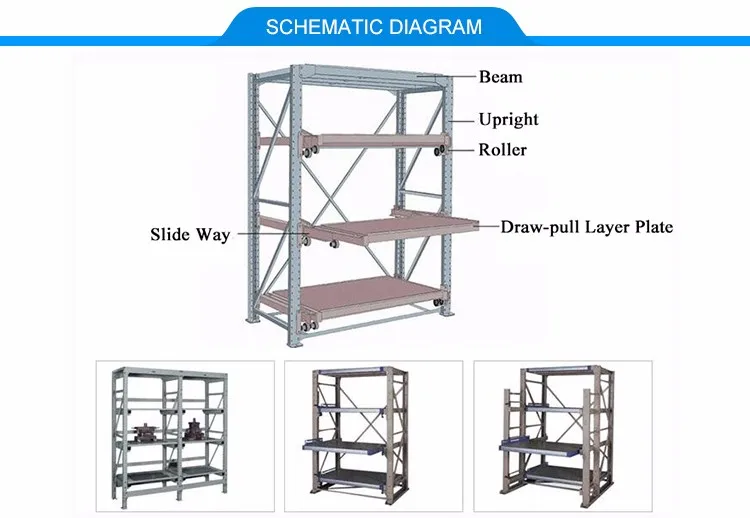

steel mold rack is mainly used for storage of all kinds of mould, which could be assembled with manual movable carriage on the top so as to easily take and retrieve the goods. The side rack was equipped with idler wheel rail on the bottom and the sliding shelf panel could be freely pulled out when loading. The middle type slide rack could carry less than 800KG/Drawer, and the heavy type slide rack could load more than 1000 KG/Drawer. The entire rack is section combination structure, which is convenient for transport, and the assembly is simple and fast and this rack possesses better safety protection device. Special drawer type mold rack can be ordered.

| 1. Features | 1) Beam levers are adjustable in 75mm pitch interval. |

| 2) Different sizes, various specifications and colors are available according to your different needs. | |

| 3) Maximizes space utility ratio while retaining optimum product accessibility. | |

| 4) Strength and rigidity prevents compression damage to goods. | |

| 5) Bottom level of pallets can be stored on the floor, lowering structure costs. | |

| 2. Material: | High grade Q235B Cold Rolled Steel |

| 3. Surface Treatment: | High-quality Powder Coating Finishing. |

| 4. Load Capacity & Dimension: | 1) Loading capacity: 200-500 kgs /pair beam. |

| 2) Height: 1000-5000mm | |

| 3) Depth: single row 600mm,3 uprights:1200mm | |

| 4) Length: 1200/1500/1800/2000/2500mm | |

| Special sizes also available to specific storage needs. | |

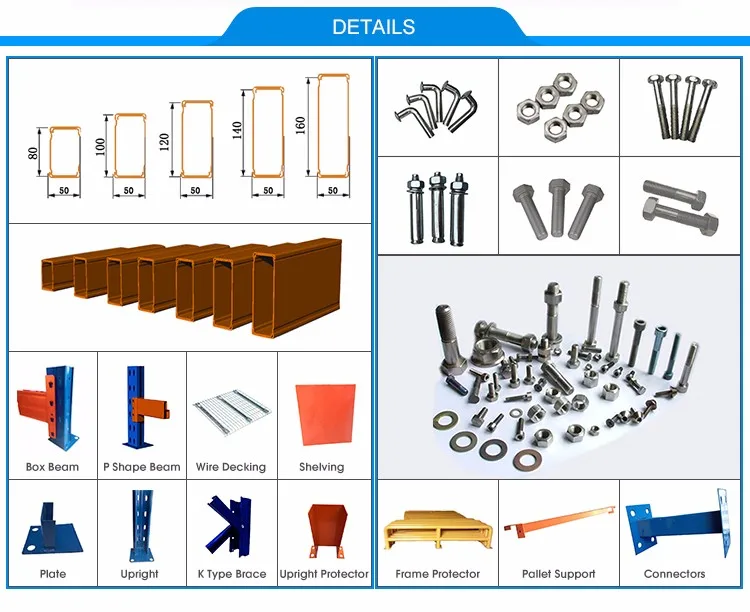

| 5. Main Parts Specs(mm): | 1) Upright: 80*40*1.0/80*40*1.5 |

| 2) Beams:60*40*1.0/60*40*1.5/80*50*1.5 | |

| 3) Horizontal & diagonal bracings: 40*24*1.5 | |

| 4) Upright Footplates: 8*8*2.0mm | |

| 5) Bolts & nuts | |

| 6) Anchors and all necessary components. | |

| 6. Certificates. | CE certified, ISO9001, |

| 7. Quick Delivery. | Within 15 workdays (negotiable), according to quantity |

1. Are you a factory or trading company?

Factory with 6 years'export experience. We have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * Depth * Length?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.

A steel mold rack is a specialized storage system designed for the efficient and secure storage of molds, dies, and other industrial tools and equipment. These racks offer several advantages, serve specific functions, have diverse applications, require regular safety checks, and demand maintenance to ensure optimal performance. Here's a comprehensive overview:

What is a Steel Mold Rack?A steel mold rack is a purpose-built storage solution constructed primarily from steel components. It features shelving, compartments, or drawers designed to accommodate and organize molds, dies, and other heavy industrial equipment. These racks are engineered to enhance organization, accessibility, and the protection of valuable tools and equipment.

Advantages of Steel Mold Rack:

Durability: Steel construction ensures the rack's long-lasting durability, even in challenging industrial environments.

Optimized Organization: These racks provide structured and organized storage, preventing damage to molds, dies, and equipment and facilitating easy retrieval.

Space Efficiency: They maximize floor space by utilizing vertical storage, allowing for efficient use of the industrial area.

Load Capacity: Steel racks can support heavy loads, ensuring the safe storage of molds and equipment.

Enhanced Safety: Proper storage reduces the risk of accidents and injuries in the workplace.

Functions and Applications:Steel mold racks are used in various industries and applications, including:

Manufacturing: Storing and organizing molds and dies used in production processes to ensure efficiency and reliability.

Metalworking: Safely storing heavy tools and equipment used in metal fabrication processes.

Automotive Industry: Supporting mold and die storage in the manufacturing of auto parts and components.

Aerospace Industry: Storing precision molds and equipment used in aircraft component manufacturing.

Safety Inspection for Steel Mold Rack:Regular safety checks for these racks should include:

Structural Integrity: Inspect for signs of damage, corrosion, or wear that may compromise stability.

Load Capacity: Ensure that the rack is not overloaded, adhering to weight limits specified by the manufacturer.

Clear Aisles: Keep aisles and walkways around the racks clear to prevent accidents.

Proper Labeling: Clearly label molds, dies, and equipment and their storage locations for easy identification.

Maintenance and Care:Proper maintenance of steel mold racks includes:

Regular Cleaning: Keep the racks clean to prevent the accumulation of dust and debris.

Lubrication: Lubricate any moving parts, such as sliding mechanisms or drawer runners, for smooth operation.

Repairs: Promptly address any damage or issues to prevent them from worsening.

Corrosion Prevention: Apply anti-corrosion treatments to steel components, especially in environments prone to moisture.

As a leading manufacturer specializing in steel mold racks, we offer customized solutions tailored to your specific needs. Contact us for a free product quote and expert advice on optimizing your mold and equipment storage system. Trust in our expertise to enhance your organization's efficiency and safety.