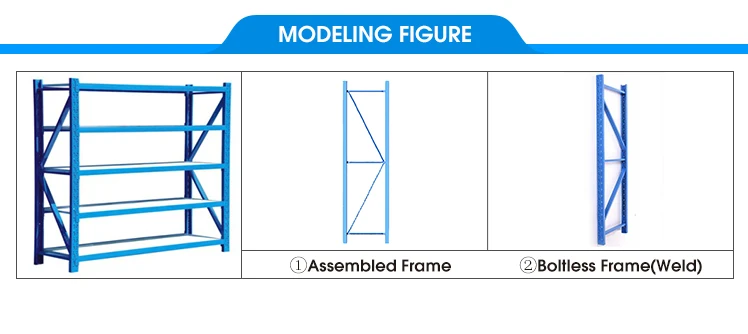

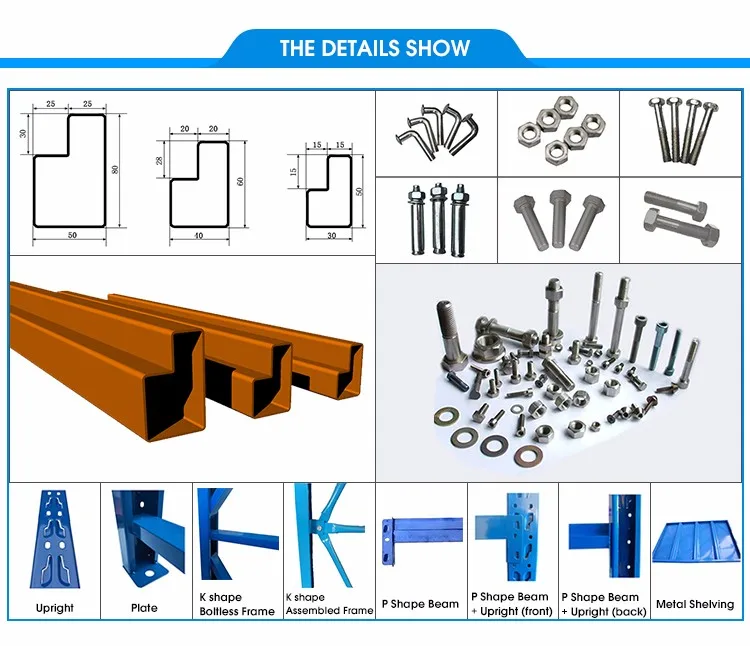

The medium duty rack consists of upright, beam and panel. Medium duty rack somprises uprights and beams hitched each other or its frame is welded type.The layer height of beam is adjusted by a pitch of 50mm.

| 1. Features | 1) Beam levers are adjustable in 75mm pitch interval. |

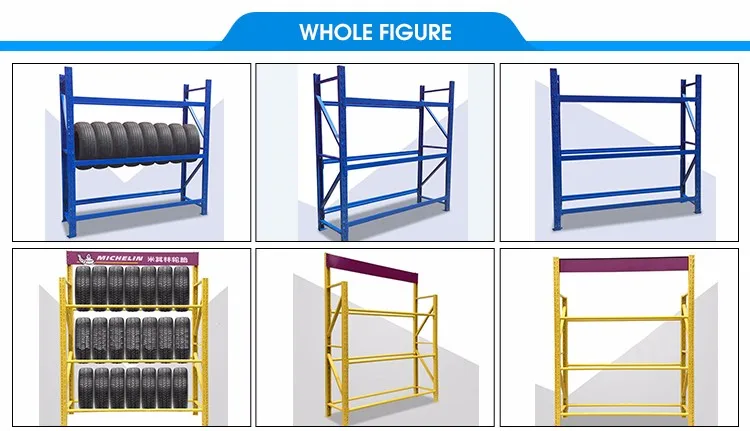

| 2) Different sizes, various specifications and colors are available according to your different needs. | |

| 3) Maximizes space utility ratio while retaining optimum product accessibility. | |

| 4) Strength and rigidity prevents compression damage to goods. | |

| 5) Bottom level of pallets can be stored on the floor, lowering structure costs. | |

|

2. Material

| High grade Q235B Cold Rolled Steel |

|

3. Surface Treatment

| High-quality Powder Coating Finishing. |

| 4. Load Capacity & Dimension | 1) Loading capacity:500-4000 kgs /pair beam. |

| 2) Height : 1500-10000mm | |

| 3) Depth of : single row 800-1200mm ( decided by pallet size), back-to-back 1800-2700mm | |

| 4) Length : 1500/2000/2500/2800/3000/3300/3500/3600mm | |

| Special sizes also available to specific storage needs. | |

| 5. Main Parts Specs(mm) | 1) Upright: 90*70*2.0mm |

| 2) Beams: 100*50*1.5/120*50*1.5/140*50*1.5/160*50*1.5/140*50*2.0/160*50*2.0mm | |

| 3) Horizontal & diagonal bracings: 40*24*1.5mm | |

| 4) Upright Footplates :120*120*3.0mm | |

| 5) Safety locking pins | |

| 6) Bolts & nuts | |

| 7) Anchors and all necessary components | |

| 6. Certificates. | CE certified, ISO9001, |

| 7. Quick Delivery. | Within 15 workdays (negotiable), according to quantity |

1. Are you a factory or trading company?

Factory with 6 years'export experience. We have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * Depth * Length?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.

A Warehouse Medium Duty Rack System is a versatile and efficient storage solution designed to optimize warehouse organization and management. It is specifically engineered to support medium-weight loads, offering a balance between heavy-duty and light-duty racking systems. Below, we outline the key aspects of warehouse medium duty rack systems:

What is a Warehouse Medium Duty Rack System?

A Warehouse Medium Duty Rack System is a storage system composed of sturdy metal components designed to store and organize goods within a warehouse or industrial environment. It provides a stable and flexible platform for storing various items, from cartons and boxes to smaller pallets.

Advantages of Warehouse Medium Duty Rack System:

Versatility: These rack systems can be adapted to store a wide range of products, making them suitable for diverse storage needs.

Space Efficiency: Medium duty racks maximize vertical storage space, allowing for the efficient use of available warehouse space.

Accessibility: Items stored on these racks are easily accessible, facilitating quicker inventory retrieval and restocking.

Cost-Effective: They offer a cost-effective storage solution compared to heavy-duty systems, making them a practical choice for medium-weight storage requirements.

Applications of Warehouse Medium Duty Rack System:

Warehouse Medium Duty Rack Systems find applications across various industries, including warehousing, logistics, manufacturing, and retail. They are commonly used for storing electronic components, automotive parts, clothing, and various other products within warehouses, distribution centers, and retail stores.

Safety Inspection for Warehouse Medium Duty Rack System:

Routine safety inspections are essential to ensure the stability and safety of the warehouse medium duty rack system. Key inspection points include:

Upright Frames: Check for any signs of bending, deformation, or rust. Ensure the frames are securely anchored to the floor.

Beams: Inspect for signs of damage, corrosion, or loose connectors. Ensure that beams are correctly seated in the uprights.

Shelving Components: Examine shelves for wear, damage, or overloading. Replace any damaged components promptly.

Load Capacity: Always adhere to the recommended weight limits for each shelf and the entire rack.

Maintenance and Care:

To maintain and extend the lifespan of your Warehouse Medium Duty Rack System:

Regular Cleaning: Keep the rack clean and free from dust and debris to prevent corrosion.

Load Management: Avoid overloading shelves and distribute weight evenly across the rack.

Repairs: Address any damage or wear immediately by replacing or repairing damaged components.

Labeling: Implement a labeling system to identify the contents of each shelf for efficient inventory management.

As a leading manufacturer of Warehouse Medium Duty Rack Systems, we offer customized solutions tailored to your specific storage needs. Contact us for a free product quote and expert consultation on optimizing your warehouse storage space.