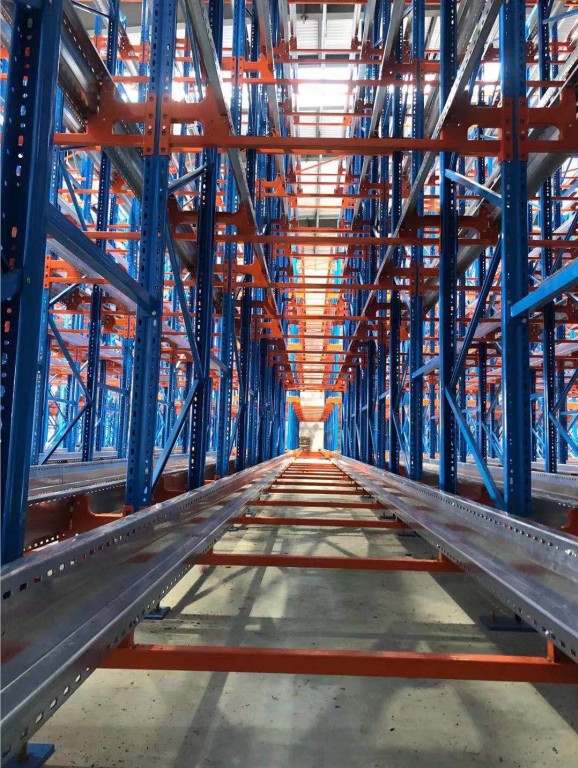

Are you in search of cutting-edge warehouse automation solutions? Look no further, as we proudly present the Pallet Shuttle, a game-changing innovation designed to streamline your warehouse operations. With its advanced features and versatile capabilities, the Pallet Shuttle is set to redefine efficiency, productivity, and cost-effectiveness in the industry.

As one of the leading pallet shuttle manufacturers, we have developed a comprehensive range of solutions to cater to diverse warehouse requirements. Our flagship product, the 4-way Pallet Shuttle, offers unparalleled flexibility and maneuverability. Its unique design enables movement in all directions, allowing seamless navigation through narrow aisles and maximizing storage capacity. Say goodbye to time-consuming manual handling and hello to optimized space utilization with the 4-way Pallet Shuttle.

For those seeking even greater efficiency, we also offer the Stow Pallet Shuttle. This innovative system integrates seamlessly with your existing racking structure, eliminating the need for expensive modifications. The Stow Pallet Shuttle operates with precision, effortlessly handling pallets and ensuring swift and accurate storage and retrieval operations. With its intelligent software and user-friendly interface, you can easily manage and monitor the system, enhancing overall operational control.

When it comes to pricing, we understand the significance of cost-effectiveness. That's why we strive to provide competitive pallet shuttle prices without compromising on quality. Our commitment to delivering value for money makes our products an attractive investment for businesses of all sizes. The Pallet Shuttle's long lifespan and minimal maintenance requirements further contribute to its cost-efficiency, ensuring a rapid return on investment.

Furthermore, automation lies at the core of the Pallet Shuttle's capabilities. By automating repetitive tasks, it reduces labor costs and minimizes the risk of human error. With advanced sensor technology and sophisticated control systems, the Pallet Shuttle operates autonomously, seamlessly integrating with your warehouse management software. This automation not only enhances productivity but also improves safety by reducing the reliance on manual labor.

The Pallet Shuttle represents a significant advancement in warehouse automation. As leading pallet shuttle manufacturers, we are proud to offer versatile solutions such as the 4-way Pallet Shuttle and the Stow Pallet Shuttle. With competitive pricing, automation capabilities, and a focus on efficiency, this innovative system is poised to revolutionize your warehouse operations. Embrace the future of warehousing with the Pallet Shuttle and unlock enhanced productivity, optimized space utilization, and improved profitability.

2. RADIO SHUTTLE RACKING SYSTEM INSTALLING VIDEO

1. Are you a factory or trading company?

Factory with 6 years'export experienceWe have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * DepthLength?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.