Telescopic design, when not nest to save space. Use of forklift or forklift can be stacked four storeys. The product combines the functions of the shelf and tray.

| 1. Features | 1. Character: conveniently use, safe and reliable; | ||||

| 2. Especially suitable for classified storage and keeping of spare parts which are packaged by box or bulk; | |||||

| 3. Can be stacked together to save space, | |||||

| 2. Material: | High grade Q235B Cold Rolled Steel | ||||

| 3. Surface Treatment: | High-quality Powder Coating Finishing. | ||||

| 4. Main Parts Specs(mm): | Model # | Size(LxDxH) | Description | Net weight | Loading Weight |

| FK1 | 60''x60''x60'' | Load 2525lbs/1147kgs | 115 lbs | 500-1500kg | |

| Max stacked(open) 4 levels | |||||

| Max stacked(close) 10 levels | |||||

| FK2 | 72''x72''x72'' | Color choices | 139 lbs | ||

| FK3 | 48''x48''x48'' | Load 3500lbs/1585kgs | 120 lbs | ||

| FK4 | 48''x48''x60'' | Max stacked(open) 4 levels | 125 lbs | ||

| FK5 | 60''x60''x48'' | Max stacked(close) 10 levels | 140 lbs | ||

| FK6 | 60''x60''x60'' | Color choices | 146 lbs | ||

| FK7 | 72''x72''x72'' | 171 lbs | |||

| Customized Dimensions are acceptable. | |||||

| 5. Certificates. | CE certified, ISO9001, | ||||

| 6. Quick Delivery. | Within 15 workdays (negotiable), according to quantity | ||||

1. Are you a factory or trading company?

Factory with 6 years'export experience. We have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * Depth * Length?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.

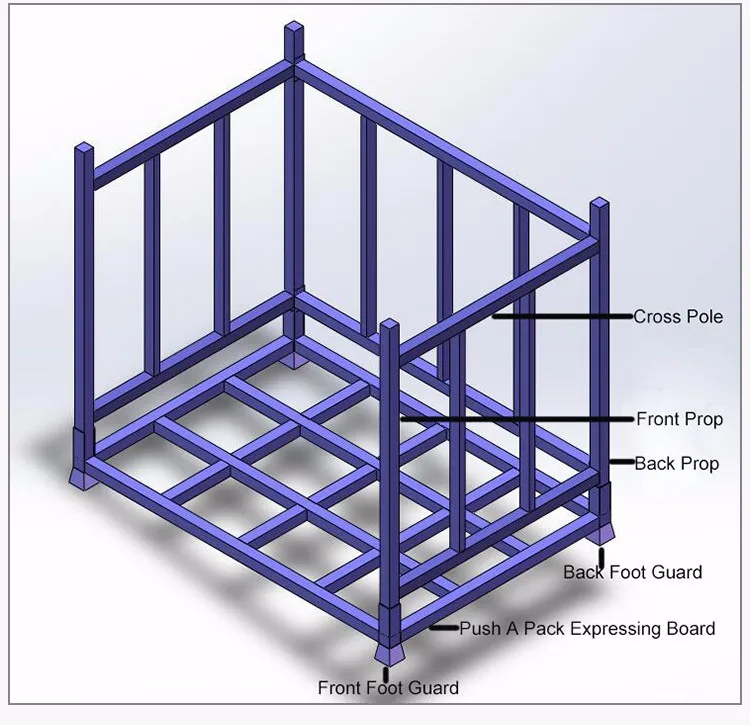

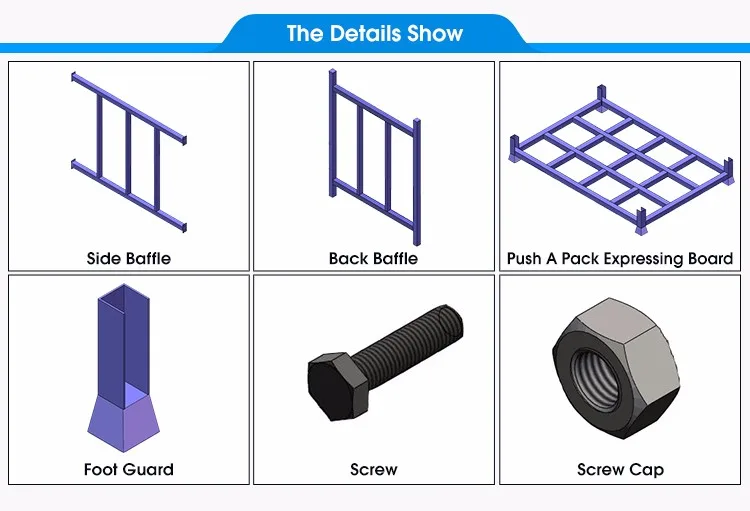

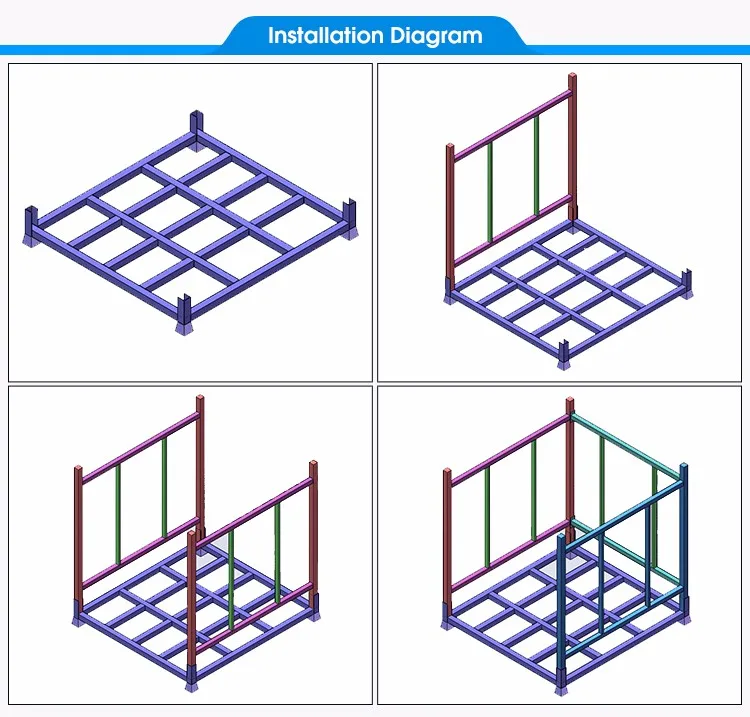

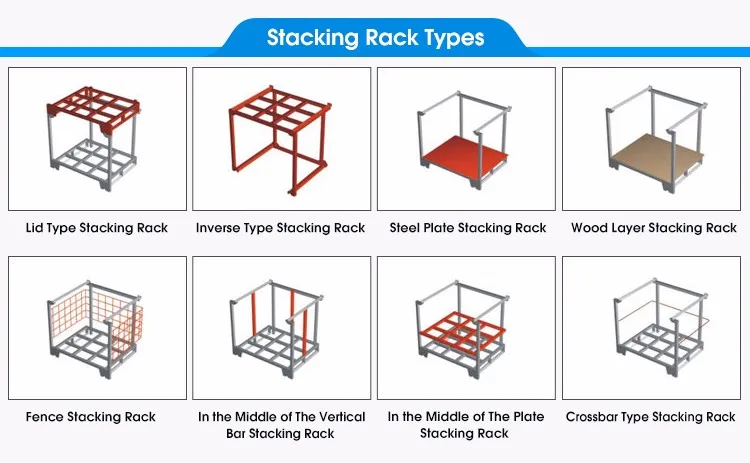

What is a Metal Storage Nestainer Rack?

A metal storage nestainer rack, also known as a nesting pallet rack or stackable storage rack, is a versatile storage solution designed for efficiently organizing and storing various goods in warehouses, factories, and distribution centers. These racks are typically constructed from durable metal materials, making them sturdy and reliable for heavy-duty storage applications.

Advantages of Metal Storage Nestainer Racks:

Space Optimization: These racks are designed to nest or stack when empty, maximizing storage space when not in use.

Versatility: They can accommodate a wide range of goods, from palletized loads to loose items, making them suitable for various industries.

Cost-Effective: Their efficient space utilization reduces the need for larger storage areas, resulting in cost savings.

Easy Handling: The racks are easy to transport and maneuver with forklifts or pallet jacks, improving material handling efficiency.

Durability: Constructed from robust metal materials, they can withstand heavy loads and provide long-term service.

Functions and Applications:

Metal storage nestainer racks serve several functions and find applications across industries, including:

Warehousing: Used for storing palletized goods, inventory items, and materials in warehouses and distribution centers.

Manufacturing: Ideal for organizing raw materials, work-in-progress items, and finished products on the production floor.

Retail: Enables efficient storage and display of merchandise in retail backrooms and stores.

Automotive: Used to store and transport auto parts and components in manufacturing and repair facilities.

Logistics: Facilitates the efficient handling and storage of goods in logistics and supply chain operations.

Safety Inspection for Metal Storage Nestainer Racks:

Regular safety inspections of metal storage nestainer racks should include:

Load Capacity: Adhere to specified weight limits to prevent overloading and structural damage.

Structural Integrity: Inspect for signs of damage, such as bent frames, welds, or connectors.

Stability: Ensure that racks are stacked securely and evenly to prevent accidents.

Aisle Clearance: Keep aisles clear of obstructions for safe movement.

Proper Handling: Train personnel on safe handling and stacking procedures to prevent accidents.

Maintenance and Care:

Proper maintenance of metal storage nestainer racks includes:

Regular Inspections: Conduct routine checks for damage or signs of wear.

Cleaning: Keep racks free from dust, debris, and spilled materials.

Repairs: Address any damage promptly to prevent further deterioration.

Coating: Apply coatings or paint to prevent corrosion and maintain appearance.

Load Distribution: Distribute heavy loads evenly across the rack to prevent overloading and maintain stability.

As a leading manufacturer specializing in metal storage nestainer racks, we offer customized solutions tailored to meet your specific storage needs. Contact us for a free product quote, and rely on our expertise to enhance the efficiency and safety of your storage and material handling operations.