Cstorage cantilever rack of pipes, wire and other profile class strip goods store has a very unique advantage. Can be divided according to the bearing capacity of light, medium and heavy three. According to the structure can be divided into sigle-sided double cantilever cantilevered shelves and shelves.

| 1. Features | 1) Beam levers are adjustable in 75mm pitch interval. |

| 2) Different sizes, various specifications and colors are available according to your different needs. | |

| 3) Maximizes space utility ratio while retaining optimum product accessibility. | |

| 4) Strength and rigidity prevents compression damage to goods. | |

| 5) Bottom level of pallets can be stored on the floor, lowering structure costs. | |

| 2. Material: | High grade Q235B Cold Rolled Steel |

| 3. Surface Treatment: | High-quality Powder Coating Finishing. |

| 4. Load Capacity & Dimension: | 1) Light duty: 50-200kg |

| 2) Medium duty: 200-800kg | |

| 3) Heavy duty:500-2000kg | |

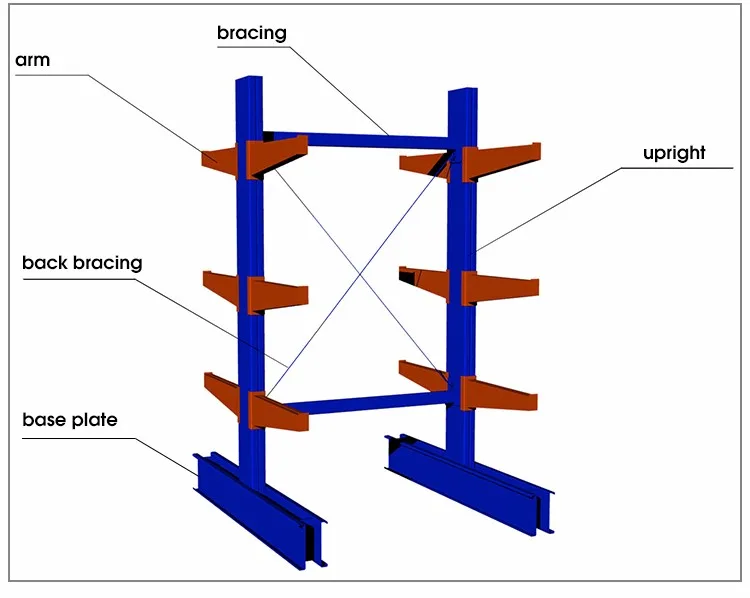

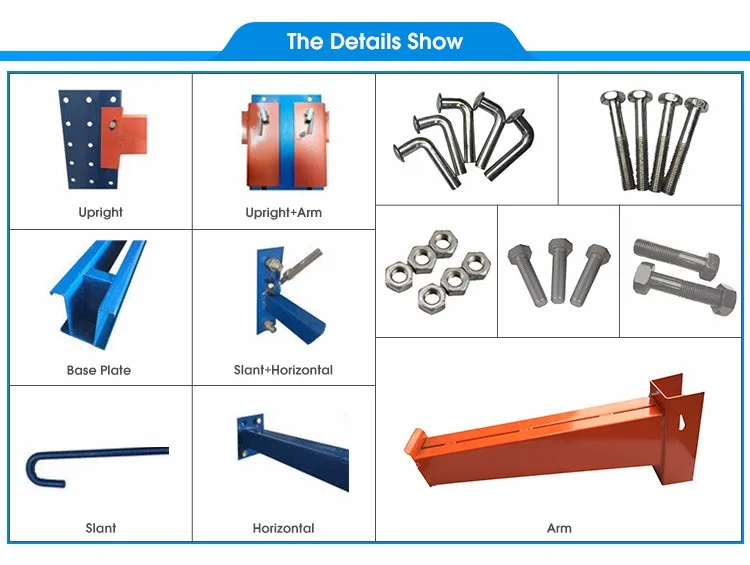

| 5. Main Parts Specs(mm): | 1) Upright: 80*200*T3.0mm |

| 2) Arms: 130mm(Bottom)*T3.0;80mm(Top)*T3.0mm | |

| 3) Back bracings:dia 8mm; | |

| 4)Row bracing:40*24*T2.0mm | |

| 5) Anchors and all necessary components. | |

| 6. Certificates. | CE certified, ISO9001, |

| 7. Quick Delivery. | FangKun® within 15 workdays (negotiable), according to quantity |

1. Are you a factory or trading company?

Factory with 6 years'export experience. We have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * Depth * Length?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.

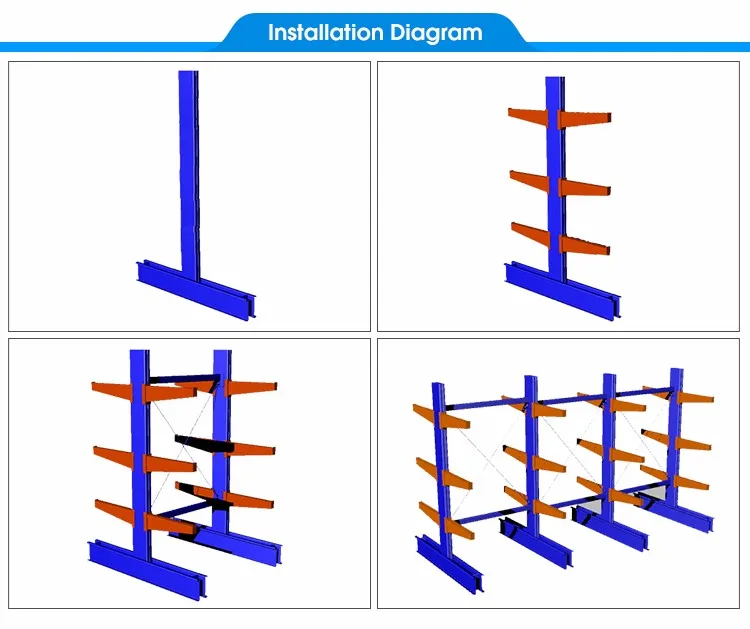

A storage cantilever rack is a specialized storage system designed for the organized and efficient storage of long and bulky items, such as lumber, pipes, steel bars, and other oversized materials. It features horizontal arms that extend from vertical columns, creating a cantilever-like structure. Here's a comprehensive overview:

Definition:A storage cantilever rack consists of vertical columns with adjustable horizontal arms extending from them. These arms are tailored to accommodate various product sizes and weights, making it an ideal solution for storing long and unwieldy items.

Advantages:

Versatile Storage: Storage cantilever racks are versatile and suitable for items of varying lengths, sizes, and weights.

Accessibility: Items stored on cantilever racks are easily accessible, facilitating quick retrieval and efficient inventory management.

Space Optimization: These racks maximize vertical storage space, making them ideal for warehouses with high ceilings.

Durability: Constructed from durable materials, they can withstand heavy loads and challenging warehouse environments.

Customization: Cantilever racks can be customized to meet specific storage requirements, ensuring adaptability across different industries.

Applications:Storage cantilever racks are widely used in industries such as construction, manufacturing, lumberyards, metal fabrication, and more. They are particularly suitable for storing items like steel beams, lumber, pipes, and other long or oversized materials.

Safety Checks:Regular safety inspections are crucial to ensure the safe usage of storage cantilever racks. Safety checks should include:

Upright Inspection: Verify that vertical columns are securely anchored to the floor and free from damage or deformation.

Arm Inspection: Examine horizontal arms for signs of bending, deformation, or damage.

Load Capacity: Ensure that the racks are not overloaded, and weight limits are adhered to.

Rack Stability: Confirm that the racks are level and securely anchored to prevent tipping.

Maintenance and Care:To maintain and extend the life of storage cantilever racks:

Regular Cleaning: Keep the rack structure clean to prevent debris buildup.

Load Management: Monitor weight limits and ensure even weight distribution on arms and columns.

Repairs: Promptly repair or replace damaged components to maintain structural integrity.

Inspections: Implement a maintenance schedule for routine inspections and servicing.

As a leading manufacturer of storage cantilever racks, we offer customized solutions tailored to your specific storage needs. Contact us for a free product quote and expert guidance on optimizing your storage space.