Drive in rack or drive through (sometimes spelled Drive-thru)is designed for storing a large number of similar goods (pallets). Pallets are placed on the supporting rails, which makes possible the high-density storage. The rack system is the most ideal for expensive storage space like cold storage warehouses.

| 1. Features | 1) Beam levers are adjustable in 75mm pitch interval. |

| 2) Different sizes, various specifications and colors are available according to your different needs. | |

| 3) Maximizes space utility ratio while retaining optimum product accessibility. | |

| 4) Strength and rigidity prevents compression damage to goods. | |

| 5) Bottom level of pallets can be stored on the floor, lowering structure costs. | |

| 2. Material: | High grade Q235B Cold Rolled Steel |

| 3. Surface Treatment: | High-quality Powder Coating Finishing. |

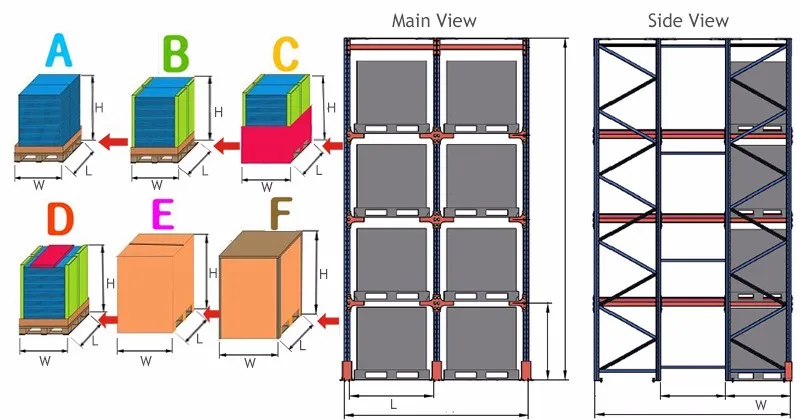

| 4. Load Capacity & Dimension: | 1) Loading capacity: 500-4000 kgs/pair beam. |

| 2) Height: 1500-10000mm | |

| 3) Depth: single row 800-1200mm ( decided by pallet size) | |

| 4) Length: 1500/2000/2500/2800/3000/3300/3500/3600 (1, 2 or 3 pallets per level, according to pallet size) | |

| Special sizes also available to specific storage needs. | |

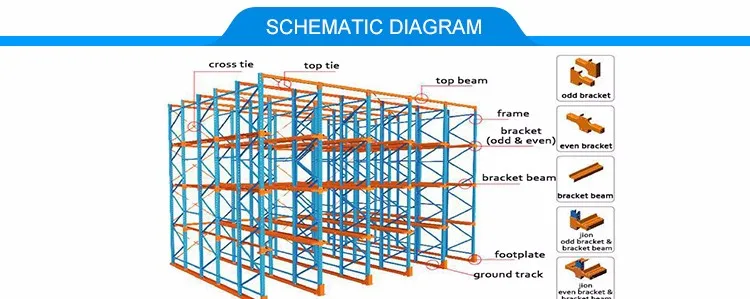

| 5. Main Parts Specs(mm): | 1) Upright: 90*70*2.0 |

| 2) Beams: 100*50*1.5/120*50*1.5/140*50*1.5/160*50*1.5/140*50*2.0/160*50*2.0 | |

| 3) Horizontal & diagonal bracings: 40*24*1.5 | |

| 4) Upright Footplates: 120*120*3.0 | |

| 5) Safety locking pins | |

| 6) Bolts & nuts | |

| 7) Anchors and all necessary components. | |

| 6. Certificates. | CE certified, ISO9001, |

| 7. Quick Delivery. | Within 15 workdays (negotiable), according to quantity |

1. Are you a factory or trading company?

Factory with 6 years'export experienceWe have been in this line more than 10 years.

2. What is the term of payment?

100% T/T or L/C at sight.

3. What is delivery times?

It depends on the order quantity and racking types. Generally within 15 days for ordinary order quantity.

4. Which port will be used as loading port?

Lianyungang or Shanghai port. Other ports are also available.

5. Are samples available?

Yes. Short sections of samples could be provided freely, but international courier costs to be borne by clients.

6. How can I get your quick quotation on our racking project?

As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotationwe need to know following info, Required Pallet Racking Dimension: Height * DepthLength?

Number of Levels?

Loading Capacity of each level?

Racking Quantity?

If you are not very sure of above info, please just let us know your storage needs. Accordingly, we'll be happy to provide with our professional proposed racking solutions as your kind reference.

7. Whether your products do quality checking & inspection before delivery?

Following factory's standard processing stepwe do inspection on every respect before delivery.

8. Do you have engineers to help us installation guiding?

We have 5 skilled and rich-experienced engineers ready for installation guiding.

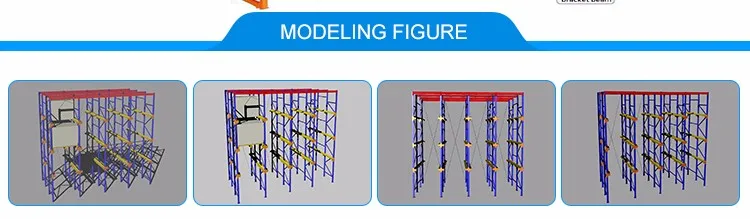

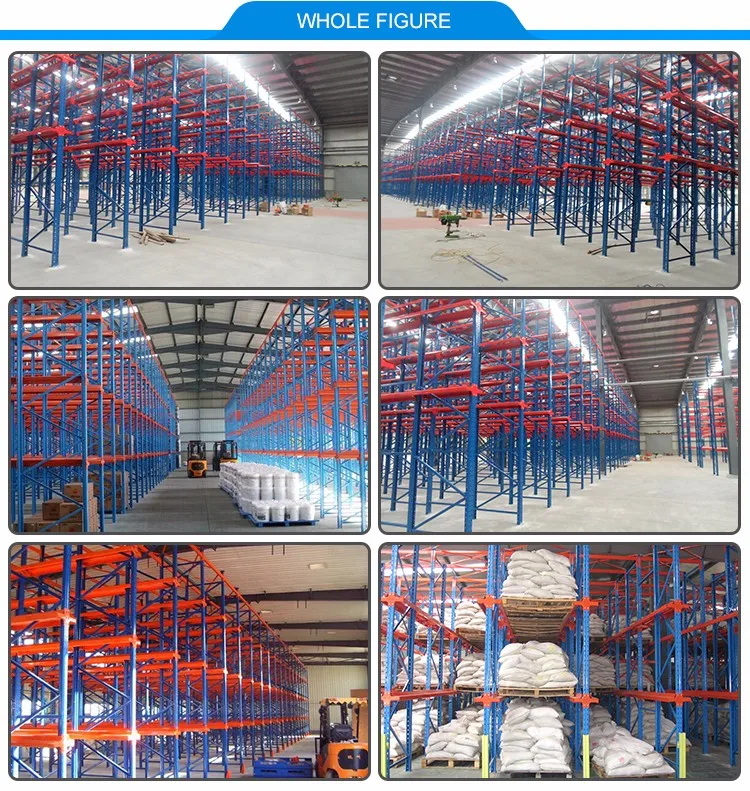

The Drive-In Warehouse Storage Pallet Racking System is a specialized storage solution designed to maximize storage capacity and efficiently store palletized goods. This system allows forklifts to drive into the racking structure, providing dense and space-efficient storage. Here's an overview of the Drive-In Warehouse Storage Pallet Racking System:

Definition:The Drive-In Warehouse Storage Pallet Racking System consists of upright frames and horizontal rails, designed to support multiple pallets stacked on top of each other in deep lanes. It is a LIFO (Last-In, First-Out) system, where the forklift enters the rack from one side to load or retrieve pallets.

Advantages:

Space Efficiency: Drive-In racking maximizes storage space utilization by eliminating aisles, making it ideal for high-density storage needs.

Cost-Effective: Fewer aisles mean lower construction and operational costs.

Bulk Storage: Well-suited for storing large quantities of similar products or items with low turnover rates.

Improved Access: Forklifts can access multiple pallets in a single lane, reducing travel time.

Customization: The system can be tailored to accommodate various pallet sizes and load capacities.

Applications:Drive-In Warehouse Storage Pallet Racking Systems are commonly used in industries like cold storage, food and beverage, manufacturing, and wholesale distribution. They are suitable for storing goods with long shelf lives, such as frozen foods, beverages, and building materials.

Safety Checks:Regular safety inspections are crucial to ensure the safety and stability of Drive-In Warehouse Storage Pallet Racking Systems. Safety checks should include:

Upright Inspection: Verify that vertical upright frames are securely anchored to the floor and free from damage.

Beam Inspection: Examine horizontal rails for signs of bending or deformation.

Load Distribution: Ensure that pallet loads are evenly distributed and within the system's weight capacity.

Clear Aisles: Keep access lanes clear of obstacles and debris.

Forklift Operator Training: Ensure forklift operators are trained in the safe use of the system.

Maintenance and Care:To maintain and prolong the life of a Drive-In Warehouse Storage Pallet Racking System:

Regular Inspections: Perform routine inspections and promptly address any damage or wear.

Load Management: Monitor weight limits and ensure even weight distribution on pallets.

Cleaning: Keep the area around the racks clean to prevent debris buildup.

Repairs: Repair or replace damaged components as needed to maintain structural integrity.

As a leading manufacturer of Drive-In Warehouse Storage Pallet Racking Systems, we offer customized solutions tailored to your specific storage requirements. Feel free to contact us for a free product quote and expert guidance on optimizing your warehouse storage space.